Table of Contents

Looking to upgrade your plywood flooring with a durable and easy-to-maintain solution? Epoxy flooring might be the answer you're looking for.

We will explore what epoxy flooring is, its benefits, and whether you can put epoxy flooring on plywood. We will also discuss the factors to consider before applying epoxy on plywood, how to prepare the surface, the steps to apply epoxy, and alternative flooring options.

Discover how you can transform your plywood floors with epoxy coating.

Epoxy flooring is a durable and versatile solution commonly used in industrial, commercial, and residential settings. It involves applying a resin coating, typically made from epoxy to surfaces like concrete, plywood, or other substrates to create a seamless, protective finish.

This type of flooring is known for its high level of durability and resistance to chemicals, impacts, and wear, making it ideal for areas with high traffic or potential exposure to harsh substances. Industries such as manufacturing plants, warehouses, automotive garages, and healthcare facilities frequently utilize epoxy flooring to maintain clean and safe work environments while also enhancing the aesthetic appeal of their spaces.

Dig deeper: How To Do Epoxy Flooring In Garage

Epoxy flooring offers numerous benefits, including exceptional durability, high adhesion properties, flexibility to withstand movement and expansion/contraction cycles, and easy maintenance.

Durability is a key aspect of epoxy flooring, ensuring long-lasting performance even in high-traffic areas. Many clients in Australia have chosen the SP20FG high-strength epoxy coat for its exceptional durability.

One notable project in Sydney, where durability was pivotal, involved the installation of epoxy flooring in a busy warehouse that required a robust solution to withstand continuous heavy machinery traffic. The SP20FG epoxy coat provided the perfect balance of durability and aesthetics, ensuring the floor maintained its pristine condition despite the challenging environment.

Epoxy flooring is known for its easy maintenance, requiring simple cleaning routines to keep the surface looking fresh. Products like ArmorGel 729 are popular for their low-maintenance properties.

One of the main advantages of epoxy flooring is its durability. Epoxy floors are resistant to stains, chemicals, water, and scratches, making them ideal for high-traffic areas. In terms of maintenance, regular sweeping or vacuuming to remove debris is essential to prevent scratching. Epoxy floors should be mopped with a gentle cleanser or a solution of water and ammonia to maintain their shine.

For tougher stains or marks, specialized products like ArmorGel 729 can be used to clean the epoxy floor without damaging the surface. These products are designed to protect the epoxy coating and can help extend the longevity of the flooring.

In industrial or commercial settings, where heavy machinery or vehicles are present, it is crucial to perform regular maintenance to avoid damage to the epoxy flooring. Using floor mats or protective pads under heavy equipment can prevent abrasions and prolong the life of the flooring.

Epoxy flooring exhibits excellent chemical resistance, protecting the substrate from spills and corrosive substances. Leading manufacturers in Australia prioritize chemical-resistant epoxy coatings for various projects.

One of the key advantages of chemical resistance in epoxy flooring lies in its ability to withstand a wide range of harsh substances without deteriorating or compromising the integrity of the floor.

Australian manufacturers renowned for their high-quality chemical-resistant epoxy products include Resincoat, Flowcrete, and Watco.

These companies are known for their innovative formulations that offer superior protection against acids, solvents, oils, and other chemicals.

From automotive workshops to food processing plants, chemical-resistant epoxy flooring finds applications in diverse environments where durability and safety are paramount.

Yes, epoxy flooring can be applied on plywood surfaces to create a durable and seamless finish. Applicators in Australia often utilize epoxy coatings on plywood substrates for various projects.

One of the key advantages of using epoxy coatings on plywood is their ability to provide a protective layer that enhances the durability of the surface and prevents damage from foot traffic, moisture, and other elements. In addition, epoxy coatings are highly customizable, allowing for a wide range of colors and finishes to suit different design preferences.

Applicators play a crucial role in ensuring the successful application of epoxy coatings on plywood. Their expertise and knowledge of the best practices in surface preparation, mixing ratios, and application techniques are essential for achieving a high-quality finish that meets the project requirements.

Successful applications of epoxy coatings on plywood can be seen in various settings, ranging from residential garages and workshops to commercial spaces like cafes and retail stores. These examples showcase the versatility and resilience of epoxy flooring on plywood surfaces."

Before applying epoxy flooring on plywood, several factors need to be considered, including the condition of the plywood surface, moisture levels, compatibility of epoxy with plywood, and the expertise of the applicator.

Surface preparation is a crucial step in ensuring the success and longevity of an epoxy flooring application. Properly preparing the plywood surface by sanding, cleaning, and repairing any imperfections is essential to achieve optimal adhesion and a smooth finish. Skilled applicators understand the intricacies of working with different surfaces and can identify and address any challenges specific to plywood. In Australia, where varying environmental conditions can impact the performance of epoxy coatings, having experienced professionals handle the application process can make a significant difference in the overall outcome.

Preparing plywood for epoxy flooring involves cleaning the surface, sanding it to create a smooth texture, and applying a suitable primer like the E100 epoxy primer to enhance adhesion and durability.

To begin the process, ensure that the plywood surface is completely free of any dust, debris, or oil residues. This can be achieved by sweeping the surface with a broom followed by wiping it down with a damp cloth and a mild detergent. Allow the surface to dry completely before proceeding to the next step.

Next, carefully sand the plywood using medium-grit sandpaper to remove any imperfections, bumps, or rough spots. This step is crucial for achieving a uniform and smooth surface that will allow the epoxy to adhere properly.

Once the surface is smooth, apply the E100 epoxy primer using a brush or roller, ensuring even coverage. The primer will provide a strong bond between the plywood and the epoxy, enhancing its durability and longevity.

Cleaning the plywood surface thoroughly is crucial before applying epoxy flooring to ensure proper adhesion and a flawless finish. Applicators in Australia prioritize surface cleanliness for successful epoxy projects.

Properly preparing the surface of the plywood serves as the foundation for a durable and visually appealing epoxy floor. Surface cleaning eliminates dust, debris, and any contaminants that could hinder the epoxy's ability to bond effectively to the substrate. This step not only enhances the aesthetic value of the flooring but also enhances its longevity by preventing premature delamination or lifting.

Commonly used cleaning methods by applicators include:

Applicators typically opt for products such as mild cleaners, degreasers, and solvent-based solutions to achieve a pristine surface before applying epoxy.

Some essential tips for ensuring a clean surface include ensuring that the plywood surface is completely dry before proceeding with the epoxy application, paying attention to corners and edges, and conducting a final inspection to address any missed spots or imperfections.

Sanding the plywood surface helps to create a smooth and uniform texture, promoting better adhesion of the epoxy coating.

By meticulously sanding the plywood surface, applicators ensure that the epoxy coating has an optimal base to adhere to, resulting in a durable and long-lasting finish. Achieving the right texture through sanding is crucial for preventing air bubbles and imperfections in the final epoxy layer. Utilizing specialized sanding tools such as orbital sanders and sanding blocks, Australian professionals are able to achieve uniformity and precision in their surface preparation process.

Applying a primer like the E100 epoxy primer is essential to enhance adhesion and ensure the longevity of the epoxy flooring on plywood surfaces. The right primer choice is crucial for a successful epoxy application.

Primers play a vital role in preparing plywood for epoxy flooring by creating a strong bond between the epoxy and plywood surface. Specifically, the E100 epoxy primer is known for its exceptional qualities in enhancing adhesion, durability, and compatibility with plywood. It acts as a protective layer that seals the wood, preventing any potential issues such as delamination or bubbling.

When selecting a primer for your project, consider factors like the type of plywood, moisture levels, and environmental conditions. The E100 epoxy primer stands out for its ability to penetrate and bond well with plywood, ensuring a secure foundation for the epoxy coating.

The process of applying epoxy flooring on plywood involves mixing the epoxy resin and hardener, applying multiple coats to achieve the desired finish, and allowing sufficient curing time for a robust surface.

To start the application process, it's crucial to ensure that the plywood substrate is clean, dry, and free of any dust or debris. This initial preparation sets the foundation for a successful epoxy flooring project. One of the best practices commonly followed by experienced applicators in Australia is to first apply a primer coat to enhance adhesion between the epoxy and plywood surface. Proper mixing of the epoxy resin and hardener is key to achieving a consistent and durable finish.

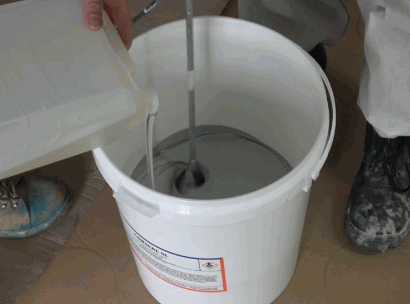

Mixing the epoxy resin and hardener accurately is crucial for achieving a proper chemical reaction and ensuring the desired properties of the epoxy flooring. Applicators in Australia follow precise mixing ratios for optimal results.

Proper mixing of epoxy resin and hardener enhances the adhesive strength and durability of the plywood, making it suitable for various applications in construction and woodworking. Ensuring a thorough blend of the components helps prevent issues like bubbles and uneven curing. Maintaining a consistent ratio not only affects the curing time but also impacts the final hardness and flexibility of the epoxy. Industry standards recommend using calibrated measuring tools and following manufacturer guidelines to achieve the best performance from the epoxy resin system.

Applying the first coat of epoxy on plywood requires precision and even coverage to establish a solid base for subsequent layers. Experienced applicators in Australia pay attention to detail during the initial coating phase.

They know that achieving uniform coverage is key to ensuring a seamless finish that enhances the durability and aesthetics of the plywood.

Proper technique, such as using a high-quality brush or roller, is crucial in preventing drips and ensuring the epoxy adheres evenly.

Challenges often arise during the first coat application, with issues like air bubbles, brush marks, or uneven drying posing threats to the final result.

To combat these problems, applicators adhere to a meticulous process of degassing the epoxy, applying thin coats, and maintaining ideal temperature and humidity levels.

The second coat of epoxy on plywood enhances adhesion, durability, and visual appeal, completing the seamless finish. Skilled applicators prioritize the application of the second coat to ensure long-lasting epoxy flooring.

Applying a second coat of epoxy not only adds an extra layer of protection but also further strengthens the bond with the substrate, ensuring enhanced resilience against wear and tear. This double-coating technique is crucial in high-traffic areas or industrial settings where the flooring is subjected to heavy loads and frequent usage.

Optimizing the second coat application involves meticulous preparation, such as proper surface cleaning and abrasion to promote adhesion. A uniform and consistent application technique is key to achieving a smooth and flawless finish, free from drips or uneven patches.

After applying the epoxy coats, allowing sufficient curing time is crucial to achieve maximum durability and strength in the plywood flooring. Applicators in Australia follow recommended curing protocols for long-lasting epoxy finishes.

Proper curing plays a vital role in ensuring that the epoxy fully polymerizes and bonds securely to the plywood surface, creating a resilient barrier against wear and tear. It allows the chemical reactions within the epoxy to complete, enhancing its hardness and chemical resistance.

Curing also significantly impacts the overall appearance of the flooring, contributing to a smooth, glossy finish that is both visually appealing and easy to maintain.

Common curing methods used by applicators in Australia include ambient temperature curing, where the epoxy is left to cure at room temperature, and accelerated curing, which involves the use of heat lamps or infrared heaters to speed up the curing process.

While epoxy flooring is a popular choice for plywood surfaces, there are alternative options like vinyl, laminate, and tile flooring that offer different aesthetics and functionalities.

Each of these alternatives has its own unique characteristics that cater to specific preferences and requirements. Vinyl flooring, for example, is known for its durability and water resistance, making it an ideal choice for areas prone to moisture exposure such as bathrooms and kitchens. Laminate flooring, on the other hand, offers a wide range of styles and colors, mimicking the look of wood or stone at a more affordable price point. Tile flooring is highly versatile, and suitable for both indoor and outdoor applications, providing a timeless and elegant finish.

When selecting the right type of flooring for a project, considerations should be made based on the intended use of the space, desired aesthetic appeal, maintenance requirements, and budget constraints. For high-traffic areas like commercial establishments or busy households, durable options such as vinyl or tile flooring may be more suitable. In contrast, laminate flooring could be a great choice for residential spaces looking to achieve a sophisticated look on a budget.

Vinyl flooring is a versatile alternative to epoxy for plywood surfaces, offering a wide range of designs, easy installation, and cost-effective solutions for various projects in Australia.

One of the key advantages of vinyl flooring is its exceptional durability, making it resistant to scratches, stains, and moisture, which is particularly beneficial for high-traffic areas like kitchens, bathrooms, and commercial spaces. Vinyl floors are available in an array of styles, from wood and stone designs to modern patterns, allowing homeowners and designers to achieve their desired look without compromising on functionality.

Regarding installation, vinyl flooring is known for its user-friendly click-lock system, enabling a smooth and efficient process that can be completed in a relatively short time frame. Maintenance is also hassle-free, requiring simple sweeping and occasional mopping to keep the floors looking pristine for years to come.

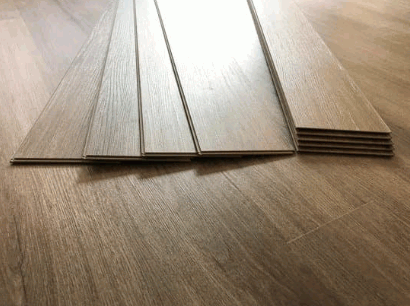

Laminate flooring provides a durable and aesthetically pleasing alternative to epoxy for plywood applications, with many skilled applicators recommending laminate for its longevity and ease of maintenance.

One of the key advantages of laminate flooring on plywood surfaces is its resistance to wear and tear, making it an ideal choice for high-traffic areas in both residential and commercial settings. The visual appeal of laminate flooring is also a significant factor, as it comes in a wide range of styles and designs to suit any interior aesthetic.

The ease of installation is another notable benefit of laminate flooring over other options. The click-and-lock installation system allows for a relatively quick and straightforward installation process, saving both time and labor costs.

When considering cost, laminate flooring is often a more budget-friendly option compared to other materials like hardwood or tile. This makes it an attractive choice for those looking to upgrade their flooring without breaking the bank.

In terms of environmental impact, laminate flooring is generally considered more eco-friendly than options like hardwood, as it requires fewer natural resources to produce. Laminate is typically easier to clean and maintain than epoxy, making it a practical choice for areas that require regular upkeep.

Tile flooring offers a stylish and durable alternative to epoxy for plywood surfaces, with a wide selection of designs, colors, and textures suitable for different residential and commercial projects in Australia.

One of the key advantages of tile flooring is its remarkable design versatility. Tiles come in various shapes, sizes, and patterns, allowing for creative customization to complement any interior aesthetic. Tiles can mimic the look of natural materials like wood or stone without the associated maintenance requirements.

Tile floors are known for their exceptional durability, making them ideal for high-traffic areas or spaces prone to moisture exposure. With proper installation and maintenance, tile floors can withstand daily wear and tear while retaining their beauty and elegance.